1.0 Purpose 目的Standardize IPQC line audit instruction and make sure in-process quality issues discovered by IPQC can be effectively controlled and timely improved, identify each functional depts work function to handle quality issues and support line improved effectively. 标准化 IPQC(技术员)的日常工作,同时,为了保证 IPQC在制程中发现的品质异常能够及时得到控制与改善,鉴别各个功能部门在处理异常时候的职能以便更有效地支援产线工作

2.0 Scope 范围Apply to Line quality audit of all manufacturing processes in HL factory. 适用于HL 工厂内生产过程的品质检查.

3.0 References 参考不合格控制程序 Non conformity control procedure3.1. QAP00083.2. QA2QI0087 生产线扣分指引Production line deduct-score direction3.3. QA2Qll0041 首件检查指引 First piece inspection instruction 3.4. QAP0009 纠正与预防控制程序 Corrective and preventive action procedure IPQC测试房巡查指引IPQC audit procedure of setting room 3.5.QA2QIl0085 制程品质控制程序 Process quality control procedure 3.6. QAP0012 3.7.QAP0013 产品标识和可追溯控制程序Product remark and traceable control procedure

4.0 Definitions 定义4.1.不合格品;不能满足鸿亮规定要求/客户要求或法律法规要求的一切原材料/半成品/成品/客户退货品Non-conformity products: All raw materials/semi-finished goods, F/G and goods returned from marketing, goods are unable to meet the requirements that requested by HL/customer and law. 4.2.IPQC∶ In-process quality control生产过程质量控制4.3.BOM∶ Bill of Material物料清单4.4. WI∶ Working Instruction 作业指导书4.5. PM∶ Packing method 包装方法4.6.FPI∶ First Piece Inspection 产品首次检验4.7. TD∶Temporary of deviation 临时偏差接受4.8.ECO∶Engineering change order∶工程更改指示4.9. NCR∶Non-Conformance report 异常发生报告4.10.NPQ∶New production qualification 新产品品质认定4.11.A&P Group∶Artworks& Packing group 包装组4.12.SER∶Sample Evaluation report 样板评估报告.

5.0 Responsibility 职责5.1.IPQC巡拉技术员负责按照相应的文件报表(如巡检报表QAF0073,100%检查表QAF0117,首件报表QAF0050等),对生产线工序进行巡香监控,仔细核对员工操作与作业指导书的要求是否一致,检查物料是否标识清晰和合理放置,工装夹具参数是否正确设置等,测试房IPQC 要每天对测试机架参数设定进行检查及校正。产品涉及返工的,还要准备返工流程,和完成返工报告,及时反馈所有发现(潜在)的影响产品质量的问题,扣留不良品和跟进处理结果,并在巡检报告中做好记录. IPQC monitor each process on line by recording related files(Such as <<IPQC in-process inspection plan>>[form No.QAF0073],<<100% checklist items>>[form No.:QAF0117],<<First Piece Inspection report>>[form No.QAF0050].etc), and check if the operators work as WI required;check if materials properly remark and place in position; look into the fixture if parameters are correctly be set and place in correct position, check and calibrate each test stand in correct parameters for every model in test booth. The goods resulted in rework, need prepare approved rework flow provided by ME and finish rework report. Record any issues in FPI report that cause product defects,on hold the products accordingly and follow up result. 5.2.生产部人员要确保开线前拉线的工序排列正确,物料及工装夹具均已完全到位,同时要检查产线上的物料与BOM 相符或有正式的文件支持使用,并被正确标识及合理放置;风批扭力及测试仪器等工装夹具的参数已设置正确.制程中要把良品与不良品区分隔离,并作好标识,及时反馈问题.线长,组长及生产主管要监督员工严格按照作业指导书操作,并参与首件制作,帮助发现问题及为分析问题原因而产生的实验,检查和执行,验证解决方案而提供支援Production Dept.need make sure line arrange correctly for each station and sequence, materials and gauges/fixtures are in place. At the same time, operators need carefully check all the materials must consist with BOM or have formal document support any deviation for the use and the materials need correctly remark and properly place in position; make sure the air drivers and test fixtures are all set to correct parameters. Al the NG/suspect materials need remark and segregated from the good materials. The line/group leaders and supervisors need monitor their operators strictly follow WI, and involve the first piece manufacturing process, feedback any issue found and execute the solutions made by analyzed team and support any verification/root cause analyzed experiments to fix solution. 5.3.QA 高技/工程师对IPQC技术员和CQA技术员反馈的问题进行确认和初步分析,并根据分析初步确定是否属于夹具仪器,来料,人员操作,文件错误,设计标准或流程管理等原因,并协同相关部门人员共同确定根本原因并验证解决措施是否得到有效实施. IPQC Sr. Tech or Engineers take charge of the confirmation of the issues found by IPQC and CQA technician, and initiate the cause analysis via check the fixture, incoming materials, operation, WI,design specification and process management...etc, then coordinate with responsible dept. to confirm the root cause and verify the solution if effectively executed5.4.ME 对制程过程发生的问题主导分析处理,并要求相尖责任部门参与讨论,制定解决方案,并负责完善WI文件的更新产线工装夹具的参数设定及维护,以及新设备的制作,修理及维护,并做好点检表(MEF0012). ME take charge of the root cause analysis for the issues found by IPQC and CQA.and take lead to discuss with responsible dept. to make solutions. At the same time, ME dept.need take responsibility for the WI update, fixtures/equipments parameters setting, fixture/gauge design, modification and record<< Machine Function inspection list >>(form No.:MEF0012) for machine daily maintenance.

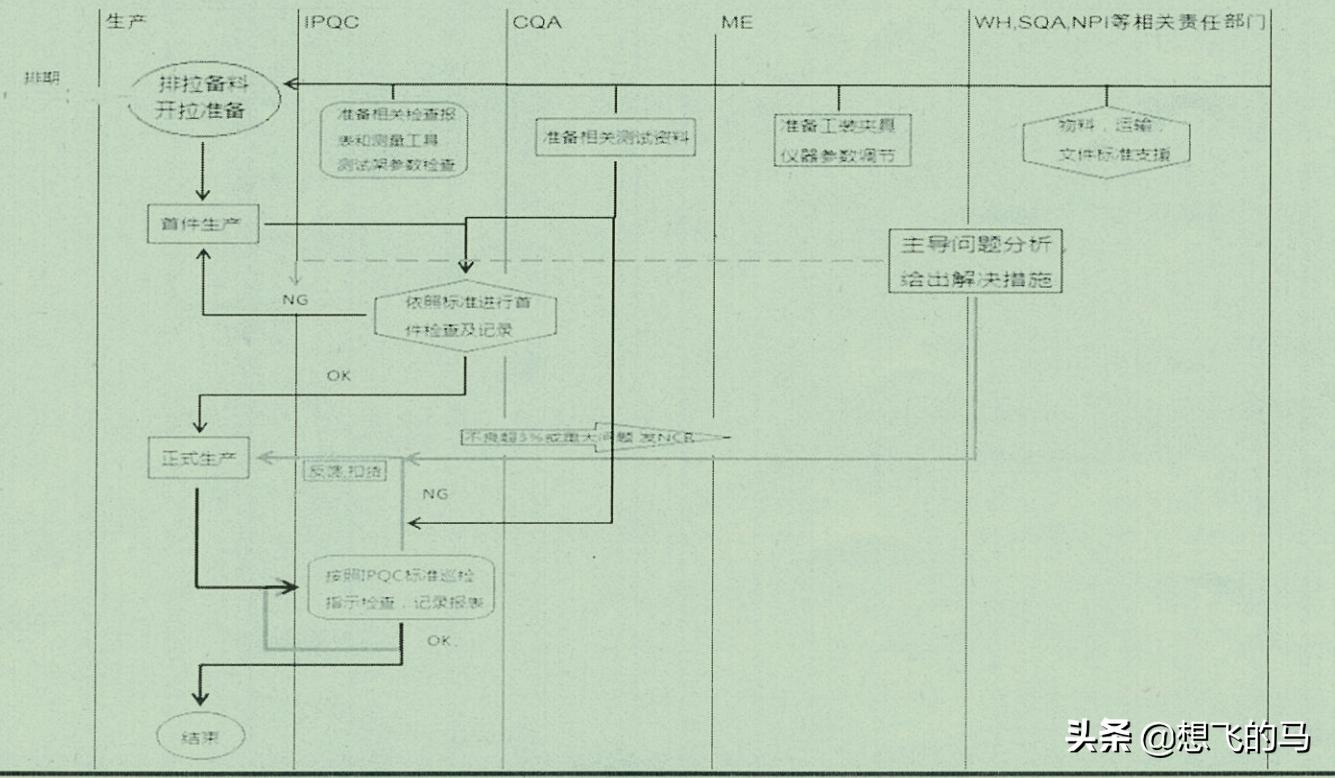

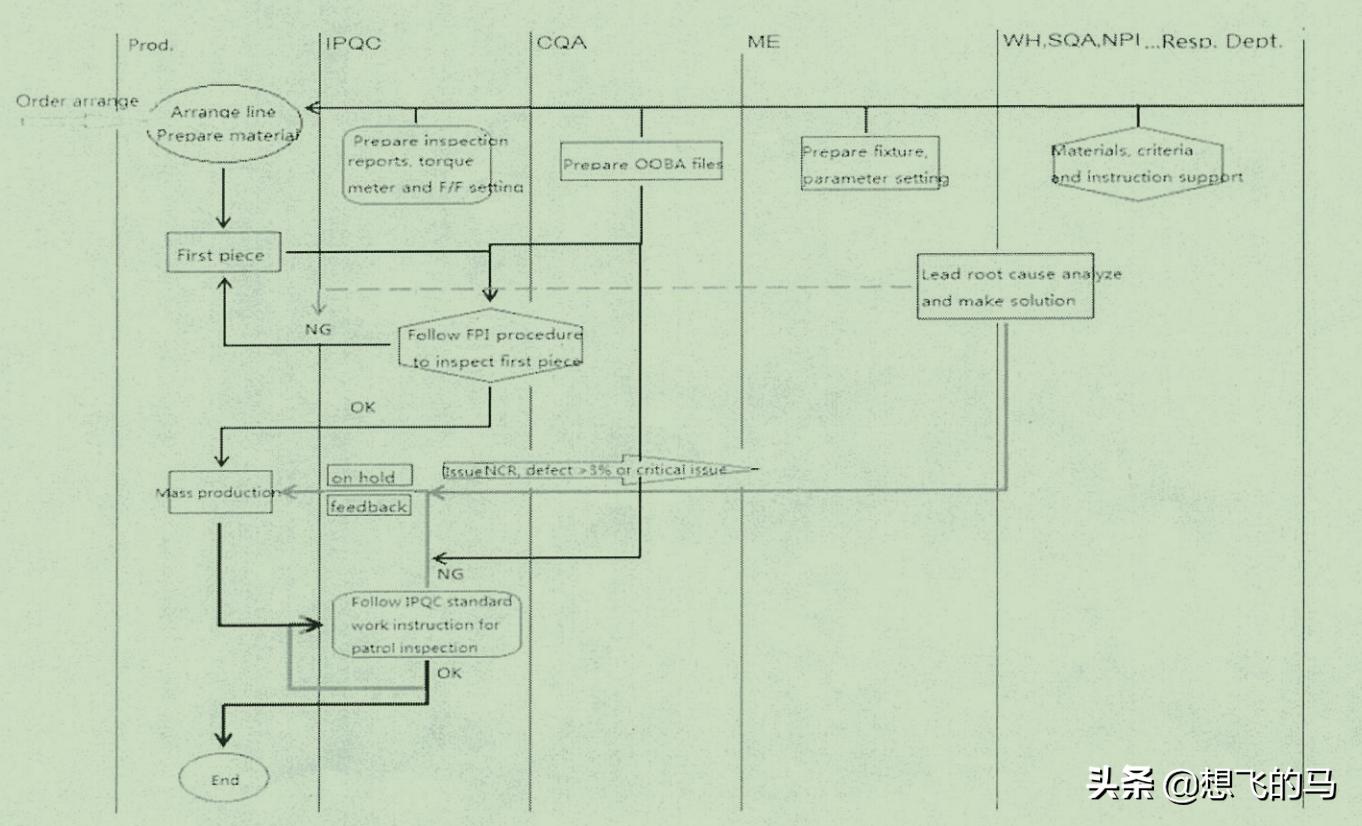

6.0 Procedure 程序6.1.开拉前的准备与检查The preparation and inspection before starting line. 6.1.1.开拉前装配线IPQC必需准备好 IPQC相尖检查报表,扭力计等,协同线长,ME 技术员检查相关夹具,检具是否齐全,设备仪器是否损坏,校准标贴是否在有效期内,相尖正确的指引文件是否已经悬挂在线上恰当的位置上. Before line start, the assembly line IPQC technician should prepare the related inspection reports and torque meters etc. Then check with line leader/ME technician on site to see if the fixtures/gauges are all in place, check instruments if calibrated and in warrant period and no damage: check WI and related instructions(if have) if correct and hang in right position. 6.1.2.测试房的IPQC 技术员,要检查测试房的油是否新鲜(当天取自油库)及要生产的型号使用的燃油配比是否正确,测试员工是否有上岗证;所使用的WI是否正确,并对测试房每个机架进行参数检查,调校,在测试房检查计划表(QAF0205)中记录任何问题 。In test room, IPQC technician need to check if the gasoline is fresh (took from gasoline tank at that day), the gasoline/oil mixture ratio should meet the models requirement, check if the operators be certified;WI correct? Set each test stand parameter in spec, record any finding in<< test room inspection plan>>(form No.:QAF0205). 6.2.开拉和首件检查Line start and First piece inspection 6.2.1.做首件时,线,组长从开始工位进行组装,IPQC技术员要跟随首件进程检查每个工位的WI是否正确,人员操作是否符合WI要求 涉及到扭力的工序还要检查扭力是否在标准范围内,装配完成后,送机子到测试房进行功能调试,IPQC确认好调试机子的参数正确,无功能问题后,才可以送到下一道工序。When the first piece starts. line/group leaders start assembly from the first station to end station. IPQC technician need follow each station to check the WI, the operation. the torque if meet requirement. After engine finished assembly, take it to test room for parameter setting, IPQC need confirm the setting engine parameters are correct and no functional issue, and then send to next station.6.2.2.首件做好后,线长组织IPQC,CQA等相关人员总结首件情况,如无问题发现即可通知开拉,并对轻微问题进行立即改正,IPQC 负责完成<<首件检查报告>>,记录重要物料的相关信息(物料编号,供应商,来料日期等)同时核对是否符合 BOM,ECO,TD 或有文件支持,工装夹具的状态和任何首件发现的问题.<<首件检查报告>>完成后,由线长及 CQA技术员共同签名确认,如发现重大异常问题,线长,IPQC应立即通知 ME,QA 高级技术员或工程师处理。After First Piece done, line leader summarizes the processes and discuss with IPQC, ME, CQA team if line can start or not, any finding should be reported and correct timely. Line can be started if no problem or tiny issues found that can be immediately correct, then, IPQC records the FPI report and record the key materials(shows on FPI report) if consist with BOM or any ECO, TD or top management email support the use, record their information (Includes P/N, vendor name, incoming date...etc).After that, check the fixture status, record any problem found. Line leader and CQA technician need confirm and sign to finish FPI report. If any serious issue happened that cause cant set up line, line leader and IPQC should raise the probiem to ME,QA Sr. Tech /Engineer to handle the issue. 6.2.3.首件检查发生问题时,IPQC工程师和 ME 应及时着手问题分析,并作出临时解决措施或根据问题的严重程度确定是否继续生产 ;同时IPQC负责及时抑问题反馈给相关部门7,如半小时内无任何改善行动,应要求生产线停拉,同时跟进处理方案的实施和追踪处理结果;ME 应根据问题的归属,推动相关责任部门对问题进行改善和纠正∶如涉及到来料问题,应由 SQA部门主导改善,推动供应商得出解决措施;标准设计问题,NPI部门负责给出解决方案或纠正行动;工装夹具及产线指导文件的问题,ME 负责纠正和改善;操作和调试问题,生产部门立即纠正并加强培训,教导..等。When serious issue happen during FPI,IPQC and ME engineer should follow the root cause analysis and check if any temporary action be applied to keep line run.At the same time, IPQC is responsible to address the issue to related department and reguire line stop if no any solution to fix the case within half an hour, and follow the solution implement & result verification; ME should work with responsible dept. to get corrective actions and improvement.(E.g. SQA dept. should take lead to handle incoming material issue, push vendor to give corrective actions; NPI dept. is responsible to give solution for design/ specification issue; any fixture/gauge and WI issue should be responsible for ME to take actions, Prod. dept should focus on operation & setting issue.)6.3.生产过程中的巡查Line audit during manufacturing 6.3.1.IPQC根据<<IPQC in-process inspection plan>>,<<100% checklist items report>>等报告按对所要求的工序进行检查并做好记录,(<<IPQC in-process inspection plan>>要求的工序每2H巡查一次,<<100% checklist items report>>要求的工序每1H巡查一次)如发现不良率超过3%或者致命/安全问题应及时反馈给QA高级技术员和生产部线长确认,然后对涉及到问题的物料和半成品进行扣留(成品通知CQA扣货),贴Reject标贴·记录所扣货品的数量.(个数/卡板数),并发出 NCR(QUAF027).按照扣分卡填写白板扣分. After line set up, IPQC should follow<<IPQC in-process inspection plan>>(--2hrs per time),<<100% checklist items report>>(--1hr per time) to check each station and record the data, as well as other reports (if have) required by some special models. If the defective ratio over 3% or any critical issue happen---this must report to QA Sr. Tech and line leader to confirm, then on hold the materials by pasting Reject label and record the qty, pallets and other necessary information (inform CQA on hold for FGs), issue IPQC<<Non-Conformance Report>>(for short:NCR)(form No.:QUAF027), fill the deduct-score on the white board with problem findings according to deduct-score Card. 6.3.1.1.组装线的IPQC工序检查应包括以下几项∶Assembly line IPQC audit instructions should includes following items:(1)检查生产部是否对所有的物料有明确的 P/N 标识.并符合有效文件.若发现物料 P/N 版本与BOM不符合,应及时告知线长停用,并在IEMS系统查是否有ECO支持,同时反馈给QA 工程师/高技查询是否有TD或邮件支持. The material should be well identified with clear P/N and consist with BOM. If found the materials P/N or version didnt consist with BOM, IPQC need inform the line leader to stop using and check whether there is ECO support in the IEMS system, then feedback to QA Sr. Tech or engineer to check if covered by TD or approve by top management via mail supports. (2)检查 BOM中物料描述是否与实物一致,若发现物料描述与实物不相符,应在J盘或工程网址中查出对应 P/N 的图纸或者 SER进行比较确认,如发现问题,应立即隔离物料,同时找相尖人员确认并跟进从理结果,直至解央。(对来米色差等一时难以判断的情况,应根据严重程度,对物料与 SER 样板进行色差对比,并根据数值判断物料是否可以继续使用). Check the BOM to see if the actual materials same as what they described, any abnormal or query, IPQC should check drawing or SER in public J disk or engineering website to clarify the query. Once any issue found. IPQC should reiect the suspect materials and find the responsible dept to handle the case and follow the result. ( for the case such as color match Issue that hard to determine then. IPQC should check with SER sample and give samples to IQC for color deviation value measurement to determine if the material can be used or not). (3)检查员工的操作是否符合WI要求,用力计检香所有要求测试扭力的工序,并测量验证产品是否达到 WI 要求相应的参数规格,同时要监测夹具/设备的稳定性.部分型号某些工位有特殊要求的,要求按照要求进行测量验证。(如四冲程的点火角度和 Timing 测量)Compare operatorsoperation with WI requirement, check torque by torque meter in the required stations, measure and verify the product parameters if meet WI specification, monitor the stability of the fixtures/instruments. For some models that have special test requirement, need follow the requirement and record the data for process monitor. (Such as 4C firing angle measurement, timing measurement..etc)(4)对主要,重要操作工序的检查是否悬挂警示牌(红牌∶安全相关岗位;黄牌∶关键岗位),是否有品质警示,员工是否有上岗资格证。Check the key stations if hang warning cards(red cards: stand for safety related stations;yellow cards:stand for significant stations), check the special stations that easily cause issue if hang quality alert and operators whether have been qualified (5)对生产线上所用的工具检查是否有效验标贴,是否在有效期内,需要用特定的工具是否符合要求如∶夹油管的尖嘴钳是否是加工成月牙形的. Check tools/gauges if they are calibrated and pasted label with a remark within warrant period, for some stations that need to use specified tool---need to check if the toolsshape met the requirements and will doesnt cause potential quality issue. (Such as assemble fuel line to carburetor tube that the clamp must no tooth and not sharp). (6)对标贴及包装资料的确认。如发现信息不全,错误或者相互间有矛盾,应知会线长及时反馈给 ME相关制作W的人员,要求其通衬包装组或市场部来提供正确的信息同时知会相余部门的工程师,主管以上级别决定是否继续生产。Inspect the labels and PM information. Any unclear, wrong or inconsistent information found, IPQC should inform line leader to require the WI maker to communicate with A&P or marketing group to provide correct information, at the same time, report the findings to engineer above to determine if continue to build. (7)IPQC应检查生产线上5S的状况,对物料,拉线台面,仪器夹具摆放的整齐程度进行检查,并依照扣分卡进行打分。IPQC should check line 5S status, review the materials location. line desk placing and fixtures/instruments location,perform score deduct according to score deduct procedure. 6.3.1.2.测试房里的IPQC工序检查应包括以下几项∶Test room IPQC inspection should includes following items:(1)检查测试房所使用的WI必须是该生产型号要求的,测试文件必须正确无误。Check all the WI in test room if meet the model requirement, make sure no mixed or wrong WI apply to test room. (2)检查机架是否能够正常使用,夹具是否有校准标贴和维护点检表,在转拉及换型号导致参数变化时,要求重新校验测试房的所有使用的机架参数设置是否符合该型号的要求,并把校准结果记录到<<流量计点检记录表>>(QUAF086)中。Check the test stand if any abnormality, and its fixture whether has calibrated label and<<machine function inspection list>>(form No.:MEF0012) for daily maintenance. When model shift or work shift, all the test stands need re-check the parameters and record<< Fuel Flow meter check record >> report (form No.:QUAF086). (3)对测试机架及人员操作的稳定性进行抽机检查,根据生产状况,每个班次至少要对每个机架进行2pCS 的抽查,并作好<<测试房检查计划>>报告,同时提交数据给高技制作 P图对参数变化进行监控。Sampling to inspect enginesfunction to verify test stand and operatorssetting performance.According to order qty, each shift at least sampling 2pcs for each stand (the more the better), then finish<<test room inspection plan>>report, and provide data to Sr. Tech to make p-chart for parameters monitor. (4)当抽机发现问题时,应交由 ME/QA等工程师分析原因并按照下列程序处理∶When found problems during sampling, inform ME and IPQC engineer to analyze root cause and follow below procedure to handle:a)若问题由机架设备导致,则该机架测试的所有产品必须扣货返工,并在<<测试房检查计划>>报告中记录好详细的问题描述。If the problem caused by test stand, all the products set at the test stand need on hold and re-set, and record in<<test room inspection plan>>report with detailed problem description. b)若问题由员工调试导致,应扣留前1小时该员工的机子,抽查 5pcs 验证是否还有同样问题发生,若无,则放货同时提醒测试房组长该员工导致的问题,要求加强监督;若抽检还能发现同样问题,则当天该员工调试的机子全部扣货,重新调试和检查,在白板记录问题并扣去相应的分数,并发NCR要求行动改善。If the problem caused by operator setting,on hold 1hr engines set by the operator and re-check 5pcs to see if the same problem found:*if no issue found, release the goods and inform line lead for the problem found and require strengthen monitor;* if same issue found, on hold all the engine set by the operator and require rework, record in white board and issue NCR for corrective actions. (5)员工调试发现坏机多时,应密切关注进程,及时反馈给高技和工程师跟进,若半小时内无法给出解决措施,应建议生产线停拉处理,所有不良机子应贴 Reject 标贴。When found operator report bad parts increased during setting, IPQC should inform engineer to follow up, if defects continuous increase and no temporary actions provided in 30 minutes, should advise line stop and reject all the suspect engines. (6)跟进新产品试产时的 OOBA 检查,传送 NPQ 测试的机子到实验室进行测试及执行部分项目的测试和验证。Follow up new product pilot run OOBA inspection,send engines to lab for NPQ test and execute some test items required by engineer. (7)每周对所使用的 Micro motion 电子流量计进行串联对比,并确保误差值小于5g/h,否则把问题设备送校验组进行校准,并作好维护检查记录表。Implement micro-motion connection check weekly to control internal range less than 5g/h. 6.3.2.按照扣分卡要求如在巡查过程中发现属于扣50分的问题,或者扣20分直接导致返工的问题提出三十分钟内没有措施纠正.要求生产线停拉. If there is any issue deducted 50 scores or deducted 20 scores and results in rework. IPQC should require line stop if thirty minutes past and no any corrective action to fix the issue after informed to responsible dept.6.4.报告的准备,蕃核.保存.Report preparation, approval and keep.6.4.1.IPQC将所有巡检过程中发现的问题记录在报表中,并交QA高级技术员,工程师蕃核.蕃核后应归档至少一年.IPQC should record all quality issues found on line and complete the inspection reports, then pass them to Sr. Tech and engineers to audit. After that, all reports must be unified keeping at least 1 year after approval. 6.4.2.首件报告至少保存3年。FPI report keeping 3 years at least.7.0 档案RecordsQAF0073 IPQC制程检查计划MEF0012 设备功能检查表QAF0050 首件报告 QUAF027 异常发生报告 QAF0205 测试房检查计划 QUAF086 流量计点检记录表QAF0117100%检查项目表 8.0 附录Appen dix流程图 Flow chart

版权声明:CosMeDna所有作品(图文、音视频)均由用户自行上传分享,仅供网友学习交流。若您的权利被侵害,请联系删除!

本文链接://www.cosmedna.com/article/195717231.html